In today’s competitive business environment, producing a good product is not enough. How quickly it reaches customers, how much it costs, and how reliably it is delivered often matter even more. This is where Supply Chain Management (SCM) plays a crucial role.

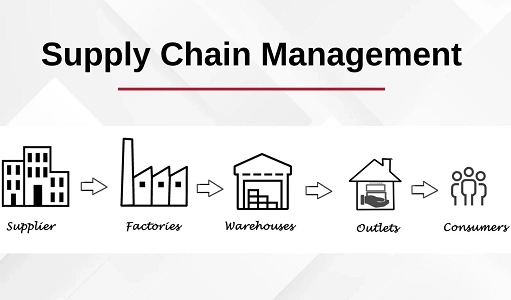

Supply chain management connects suppliers, manufacturers, warehouses, transporters, distributors, and customers into one coordinated system. When managed well, it reduces costs, improves efficiency, and increases customer satisfaction. When managed poorly, it can disrupt operations, increase expenses, and damage reputation.

To understand its true impact, let’s examine the advantages and disadvantages of supply chain management in detail, step by step.

What Is Supply Chain Management?

Supply Chain Management is the process of planning, controlling, and coordinating the flow of goods, services, information, and money from raw material suppliers to the final customer.

It includes:

- Procurement of raw materials

- Production and inventory management

- Warehousing and logistics

- Distribution and delivery

- Information and relationship management

The main goal is to deliver the right product, at the right time, at the right cost.

Advantages of Supply Chain Management

1. Cost Reduction

One of the biggest advantages of effective SCM is cost efficiency.

It helps in:

- Reducing inventory holding costs

- Minimizing transportation expenses

- Avoiding wastage and duplication

Better coordination lowers overall operational costs.

2. Improved Operational Efficiency

SCM streamlines business processes.

It:

- Removes bottlenecks

- Improves coordination between departments

- Speeds up production and delivery

This leads to smoother and faster operations.

3. Better Inventory Management

Supply chain management optimizes inventory levels.

It ensures:

- Neither excess stock nor shortages

- Lower storage and carrying costs

- Reduced risk of obsolescence

This improves cash flow and working capital management.

4. Faster Delivery and Lead Time Reduction

Efficient SCM shortens delivery times.

It:

- Improves logistics planning

- Reduces delays

- Ensures timely availability of products

Fast delivery increases customer satisfaction.

5. Improved Customer Satisfaction

A reliable supply chain improves service quality.

Customers benefit from:

- On-time delivery

- Product availability

- Consistent quality

Satisfied customers lead to repeat business and loyalty.

6. Better Supplier Relationships

SCM encourages collaboration with suppliers.

This results in:

- Long-term partnerships

- Better pricing

- Improved quality of raw materials

Strong relationships improve reliability.

7. Increased Competitive Advantage

Companies with efficient supply chains perform better.

They can:

- Offer lower prices

- Respond faster to market changes

- Adapt quickly to customer demand

SCM becomes a strategic advantage.

8. Improved Demand Forecasting

Supply chain management uses data and analysis.

This helps in:

- Predicting demand accurately

- Planning production better

- Reducing uncertainty

Better forecasting reduces business risk.

9. Risk Management and Flexibility

SCM helps identify and manage risks.

It allows:

- Alternative sourcing

- Backup logistics plans

- Quick response to disruptions

This improves business resilience.

Disadvantages of Supply Chain Management

Despite its benefits, SCM also has challenges.

1. High Implementation Cost

Setting up an effective SCM system is expensive.

Costs include:

- Technology and software

- Infrastructure upgrades

- Training employees

Small businesses may find it unaffordable.

2. Complex System to Manage

Supply chains involve many parties.

Managing:

- Suppliers

- Transporters

- Warehouses

becomes complex and requires coordination at every level.

3. Dependence on Suppliers and Partners

Businesses rely heavily on external parties.

Problems arise when:

- Suppliers delay delivery

- Transport fails

- Partners do not meet standards

One weak link can disrupt the entire chain.

4. Risk of Supply Chain Disruptions

Unexpected events can break supply chains.

Examples include:

- Natural disasters

- Political instability

- Pandemics or strikes

Such disruptions can stop production completely.

5. Technology Dependence

Modern SCM relies heavily on technology.

System failures, cyberattacks, or software issues:

- Can halt operations

- Cause data loss

Strong IT security is essential.

6. Requires Skilled Workforce

Effective SCM needs trained professionals.

This includes:

- Supply chain planners

- Logistics experts

- Data analysts

Lack of skilled staff reduces effectiveness.

7. Information Sharing Risks

SCM requires sharing sensitive information.

This includes:

- Pricing

- Demand data

- Production plans

Poor data protection can lead to misuse or leaks.

8. Difficult to Measure Performance Accurately

SCM performance depends on many variables.

Measuring:

- Supplier performance

- Logistics efficiency

- Customer satisfaction

accurately can be challenging.

9. Resistance to Change

Implementing SCM often changes workflows.

Employees and partners may:

- Resist new systems

- Prefer old methods

Change management becomes necessary.

When Supply Chain Management Works Best

Supply chain management works best when:

- Demand is predictable

- Partners cooperate actively

- Technology is reliable

- Management commitment is strong

Coordination and communication are key.

Final Thoughts

Supply chain management is a powerful driver of efficiency, cost control, and customer satisfaction. A well-managed supply chain strengthens competitiveness, improves reliability, and supports long-term business growth. In many industries, it is no longer optional—it is essential.

However, SCM is not simple. High costs, complexity, dependence on external partners, and disruption risks can create serious challenges. Without proper planning and skilled execution, supply chain systems may fail to deliver expected benefits.

The real value of supply chain management lies in balance. When technology, people, and processes work together smoothly, SCM becomes a strong foundation for sustainable and resilient business success.