In business, not all items are equally important. Some products or materials consume a large portion of money and management attention, while others have very little financial impact. Treating everything the same leads to wasted effort and poor control. This is where ABC analysis becomes useful.

ABC analysis is a simple but powerful inventory control technique. It helps management focus on what really matters instead of spreading attention evenly across all items. However, while it improves efficiency, it also has limitations. To use it effectively, one must understand both its advantages and disadvantages.

What Is ABC Analysis?

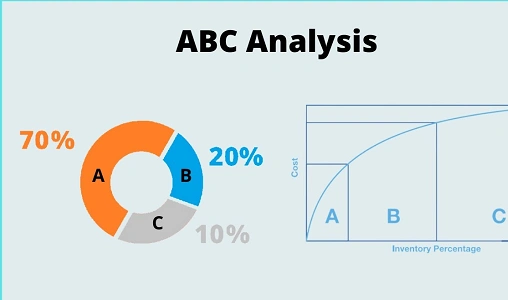

ABC analysis is an inventory management technique that classifies items into three categories based on their value and importance:

- A items: High-value items with low quantity but high consumption value

- B items: Moderate value and moderate importance

- C items: Low-value items with high quantity but low consumption value

The idea is based on the Pareto principle (80/20 rule), where a small number of items account for a large portion of total inventory value.

Advantages of ABC Analysis

1. Better Inventory Control

The biggest advantage of ABC analysis is improved control.

By focusing more on A items:

- Management can closely monitor critical inventory

- Losses and wastage are reduced

- Stock-outs of important items are avoided

This leads to more effective inventory management.

2. Efficient Use of Management Time

Management time is limited.

ABC analysis ensures that:

- Maximum attention is given to high-value items

- Less time is wasted on low-impact items

This improves decision-making efficiency.

3. Cost Reduction

ABC analysis helps reduce inventory-related costs.

By tight control over A items:

- Excess stock is avoided

- Carrying and holding costs are minimized

This improves overall cost efficiency.

4. Improved Purchasing Decisions

Purchasing policies can be tailored for each category.

For example:

- A items: Frequent review, strict purchasing control

- B items: Moderate supervision

- C items: Bulk purchase with simple control

This leads to smarter and more economical buying decisions.

5. Better Stock Availability

Critical items receive priority.

As a result:

- Important materials are rarely out of stock

- Production interruptions are reduced

This supports smooth operations.

6. Simple and Easy to Apply

ABC analysis is easy to understand and implement.

It:

- Does not require complex calculations

- Can be applied to most types of inventory

This makes it suitable even for small businesses.

7. Supports Other Inventory Techniques

ABC analysis works well with other methods.

It can be combined with:

- EOQ

- Just-in-Time

- Inventory budgeting

This improves overall inventory planning.

Disadvantages of ABC Analysis

Despite its usefulness, ABC analysis has limitations.

1. Ignores Criticality of Items

ABC analysis is based only on value.

It does not consider:

- Importance of items for production

- Availability or lead time

A low-value C item may still be critical for operations.

2. Not Suitable for All Businesses

ABC analysis works best where inventory value varies significantly.

It may not be suitable for:

- Service industries

- Businesses with uniform item values

In such cases, classification becomes less meaningful.

3. Requires Accurate Data

ABC analysis depends on reliable data.

Incorrect data on:

- Consumption

- Prices

can lead to wrong classification and poor decisions.

4. Static in Nature

ABC analysis is usually based on past data.

It:

- Does not automatically reflect demand changes

- Needs frequent updating

Without updates, classifications become outdated.

5. Overemphasis on Cost

The method focuses mainly on monetary value.

It ignores factors like:

- Risk

- Scarcity

- Supplier reliability

This can distort priorities.

6. May Create Neglect of C Items

Too much focus on A items can lead to neglect of C items.

This may result in:

- Stock-outs of low-value but necessary items

- Operational delays

Balance is still required.

7. No Standard Classification Rule

There is no fixed rule for classification.

Different firms may:

- Use different cut-offs

- Classify items differently

This reduces comparability and consistency.

When ABC Analysis Works Best

ABC analysis is most effective when:

- Inventory values differ significantly

- Data is regularly updated

- Used along with other control methods

- Management understands its limitations

It should guide attention, not replace judgment.

Final Thoughts

ABC analysis is a practical and widely used inventory control tool. It helps businesses focus on the most valuable items, reduce costs, and use management time more effectively. For many organizations, it brings clarity and discipline to inventory management.

However, ABC analysis is not a complete solution. Its focus on value alone can overlook operational importance and risk factors. Blind reliance on this method can lead to poor decisions.

The real strength of ABC analysis lies in selective control. When combined with experience, regular review, and complementary techniques, it becomes a powerful tool for efficient and balanced inventory management.